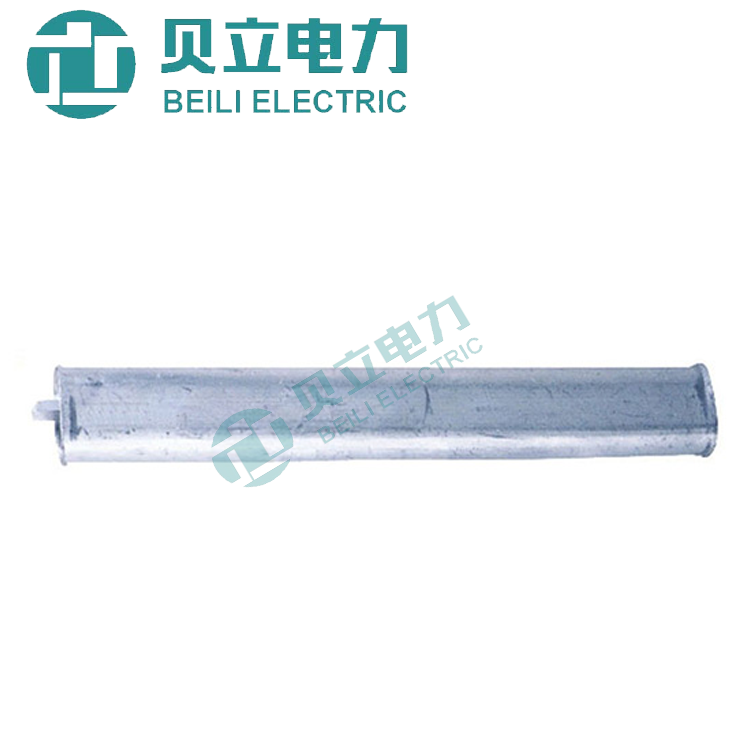

JJE Taxanaha C Nooca Transformer Clamp

Sharaxaad:

C-clamp for transformer wuxuu ka samaysan yahay aluminium aluminium gaar ah, kaas oo leh sifooyin firfircoon oo xoog leh, wuxuuna ku habboon yahay kirishbooyada naxaasta iyo korriinka kala-guurka naxaasta-aluminiumka labadaba.Isku-xidhkaani waxa inta badan loo isticmaalaa in lagu xidho oo laga gooyo istaarka iyo fiilooyinka Transformers, furayaasha iyo qalabka kale.

Mid ka mid ah cidhifyada si buuxda looma xidho iyada oo la isku xidho dhejiska gudaha ee gudaha, iyo dhamaadka kale wuxuu ku xiran yahay siligga.Qalabka dhegta leh ayaa isku xira tuubbada wareegsan ee gudaha iyo siliga.Dhuumaha wareegsan ee qayb ahaan xiran ayaa leh dabacsanaan waxayna kaydin kartaa oo sii deyn kartaa siliga iyo urka.Tamarta ay keento balaadhinta kulaylka iyo foosha

Marka culeysku kordho, xannibaadda kulaylka ee siligga ayaa balaadha, tuubada duntu waxay noqon doontaa mid yar oo fidsan.Marka siliga la isku xiro, tuubada dunta ayaa dib u soo ceshatay sababtoo ah dabacsanaanteeda, cadaadiska joogtada ah ee joogtada ah ayaa la ilaaliyaa (saamaynta wada-neefsiga).

Xirmooyinka dhuuban ee lagu rakibay inta u dhaxaysa tuubada dunta ah iyo fiilada waxay soo saari kartaa cadaadis dhinaca sare ah oo hoos yimaada ficil gaar ah, si ay u xirto nooca C-ga iyo fiilada, iyo cadaadis ku filan oo xiriir ah oo leh transformer iyo urka, si ay u beddelato fur Tiirku wuxuu si buuxda u dhigmaa tuubada dunta gudaha ku jirta, taasoo si wayn u kordhisa xidhiidhka u dhexeeya istaadhka beddelka iyo C-clamp, waxayna ilaalisaa waxqabadka xidhiidhka.

Heerka danab lagu dabaqi karo: 380v, 10kV, 110kV, 220kV, 330kV, waxaa loo isticmaali karaa in lagu xidho madaxa aluminium silig aluminium, madaxa aluminium silig naxaas ah, madaxa aluminium silig aluminium

Astaamaha:

1. Ku neefso fiilooyinka iyo dariiqyada, baabi'iso qulqulka kulaylka ee cilladda siliga iyo isku xirka qalabka

2. Si wax ku ool ah u yaree luminta xidhiidhka

3. In si weyn loo yareeyo khasaaraha baaxadda leh ee qalabka iyo korontadu ka go’do kulaylka

4. Rakibaadda ayaa ah mid aad u habboon, degdeg ah oo aad u yaraynaysa arrimaha aadanaha

5. Dayactir la'aan iyo dayactir la'aan si loo horumariyo hufnaanta maalgelinta

6. Looma baahna qalab gaar ah, kaas oo wanaajin kara faa'iidada maalgashiga ee lacagaha

7. Waxay si weyn u kordhisaa xidhiidhka u dhexeeya qalabka iyo fiilooyinka, hagaajinta nolosha adeegga

8. Hawlgallada la isku halayn karo ee muddada-dheer ee khadadka iyo qalabka ayaa bixiya dammaanad xooggan

| Qaabka | Stud lagu dabaqi karo | Maamule lagu dabaqi karo | Dhexroorka siliga | Qaabka | Stud lagu dabaqi karo | Maamule lagu dabaqi karo | Dhexroorka siliga |

| SP-B50 | M12 | LJ (TJ) 25 | 6.36 | SP-B94 | M20 | LJ (TJ) 150 | 15.75 |

| SP-B51 | M12 | JKLYJ35 | 7 | LGJ120 | 17.74 | ||

| LJ (TJ) 35 | 7.5 | SP-B95 | M20 | LJ (TJ) 120 | 14.25 | ||

| LGJ35 | 8.16 | LGJ95 | 13.6 | ||||

| SP-B52 | M12 | JKLYJ50 | 8.3 | SP-B71 | M16 | LJ (TJ) 35 | 7.5 |

| LJ (TJ) 50 | 9 | LGJ35 | 8.16 | ||||

| LGJ50 | 9.6 | LJ (TJ) 50 | 9 | ||||

| SP-B53 | M12 | JKLYJ70 | 10 | SP-B72 | M16 | LGJ70 | 11.4 |

| LJ (TJ) 70 | 10.8 | LJ (TJ) 70 | 10.8 | ||||

| LGJ70 | 11.4 | JKLYJ70 | 10 | ||||

| SP-B54 | M12 | LJ (TJ) 95 | 12.12 | LGJ50 | 9.6 | ||

| LJ (TJ) 120 | 14.25 | SP-B73 | M16 | LJ (TJ) 95 | 12.12 | ||

| SP-B55 | M12 | LJ (TJ) 150 | 15.75 | LGJ95 | 13.6 | ||

| JKLYJ185 | 16.2 | LJ (TJ) 120 | 14.25 | ||||

| LJ (TJ) 185 | 17.5 | SP-B74 | M16 | LJ (TJ) 150 | 15.75 | ||

| SP-B56 | M12 | LJ (TJ) 240 | 20 | LGJ120 | 15.74 | ||

| SP-B61 | M14 | LJ (TJ) 35 | 7.5 | SP-B75 | M16 | LJ (TJ) 185 | 17.5 |

| LGJ35 | 8.16 | LJ (TJ) 150 | 17.1 | ||||

| LJ (TJ) 50 | 9 | JKLYJ185 | 16.2 | ||||

| SP-B62 | M14 | LGJ70 | 11.4 | SP-B76 | M16 | LGJ185 | 18.9 |

| LJ (TJ) 70 | 10.8 | JKLYJ240 | 18.4 | ||||

| JKLYJ70 | 10 | SP-B77 | M16 | LJ (TJ) 240 | 20 | ||

| SP-B63 | M14 | LGJ50 | 9.6 | SP-B81 | M18 | LJ (TJ) 35 | 7.5 |

| LJ (TJ) 95 | 12.12 | LGJ35 | 8.16 | ||||

| LGJ95 | 13.6 | LJ (TJ) 50 | 9 | ||||

| LJ (TJ) 120 | 14.25 | SP-B82 | M18 | LGJ70 | 11.4 | ||

| SP-B64 | M14 | LGJ120 | 15.74 | LJ (TJ) 70 | 10.8 | ||

| LJ (TJ) 150 | 15.75 | JKLYJ70 | 10 | ||||

| SP-B65 | M14 | LGJ150 | 17.1 | SP-B83 | M18 | LJ (TJ) 120 | 14.25 |

| LJ (TJ) 185 | 17.5 | LGJ95 | 13.6 | ||||

| SP-B66 | M14 | LGJ185 | 18.9 | LJ (TJ) 95 | 12.12 | ||

| JKLYJ240 | 18.4 | SP-B84 | M18 | LJ (TJ) 150 | 17.75 | ||

| SP-B67 | M14 | LJ (TJ) 240 | 20 | LGJ120 | 17.74 | ||

| SP-B91 | M20 | LJ (TJ) 240 | 20 | SP-B85 | M18 | LJ (TJ) 185 | 17.5 |

| SP-B92 | M20 | LGJ185 | 18.9 | LGJ150 | 17.1 | ||

| JKLYJ240 | 18.4 | JKLYJ185 | 16.2 | ||||

| SP-B93 | M20 | LJ (TJ) 185 | 17.5 | SP-B86 | M18 | LGJ185 | 18.9 |

| LGJ150 | 17.1 | JKLYJ240 | 18.4 | ||||

| JKLYJ185 | 16.2 | SP-B87 | M18 | LJ (TJ) 240 | 20 |

Rakibaadda:

1. Go'aami qaabka: Si taxadar leh u hubi in siligu uu la mid yahay qaabka lagu calaamadiyay xajinta, sida: Model ZJC-B51, M12 macnaheedu waa in furaha rasaasta uu yahay M12, iyo JKLJ35 waa siliga baxaya.

2. Hagaaji curiyaha “g”-qaabeeya: u marooji saacadda u wareegta furaha, curiyaha qaabaysan ee “g” waa la maroojin karaa oo dibadda ayaa loo fidinayaa.Qodobbada: Baloogga dheddigga ah wuxuu la jaan qaadayaa dhinicii transformer-ka, baloogga labka ah waxaa lagu dhejiyaa siliga, ka dibna waxaa la soo saaraa baloogga dhuuban si loo sameeyo (labada baloogyada waxaa loo rogaa xagal gaar ah).

3. Geli fiilooyinka iyo boolasha meesha: Geli fiilooyinka jeexjeexyada "g", oo ku dheji isku xirka qaanso-qaabeeya sida waafaqsan dusha sare ee arc.Waxaad geli kartaa boolalka dhabarka si ay boolaluhu ugu jiraan booska dhexe ee sare ee dhejiska.Ku dheji furayaasha furaha.)

4. Hubi in si sax ah loo rakibay: Markaad adkaynayso boltka, dhawrka dunood ee ugu dambeeya waa inay lahaadaan dareen cad oo xoog ah.Riix dhejiska dhejiska si siman oo ku riix shayga qaabaysan ee "g".Cunsurka “g” waa in uu yara qalloocan yahay.(Ka dib marka la rakibo, jiid fiilada oo soo bixi adigoo jiidaya ama jiidaya si aad u aragto haddii siliga iyo ka soo bixistu ay adag yihiin)

5. Burburinta: Fur furayaasha, geli kaashawiito inta u dhaxaysa baloogga riixaya iyo curiyaha “C”, oo xoog ku soo jiid si aad kor ugu dhejisid baloogga riixaya.